Encoding tapes: “The value lies in this new data opportunity”

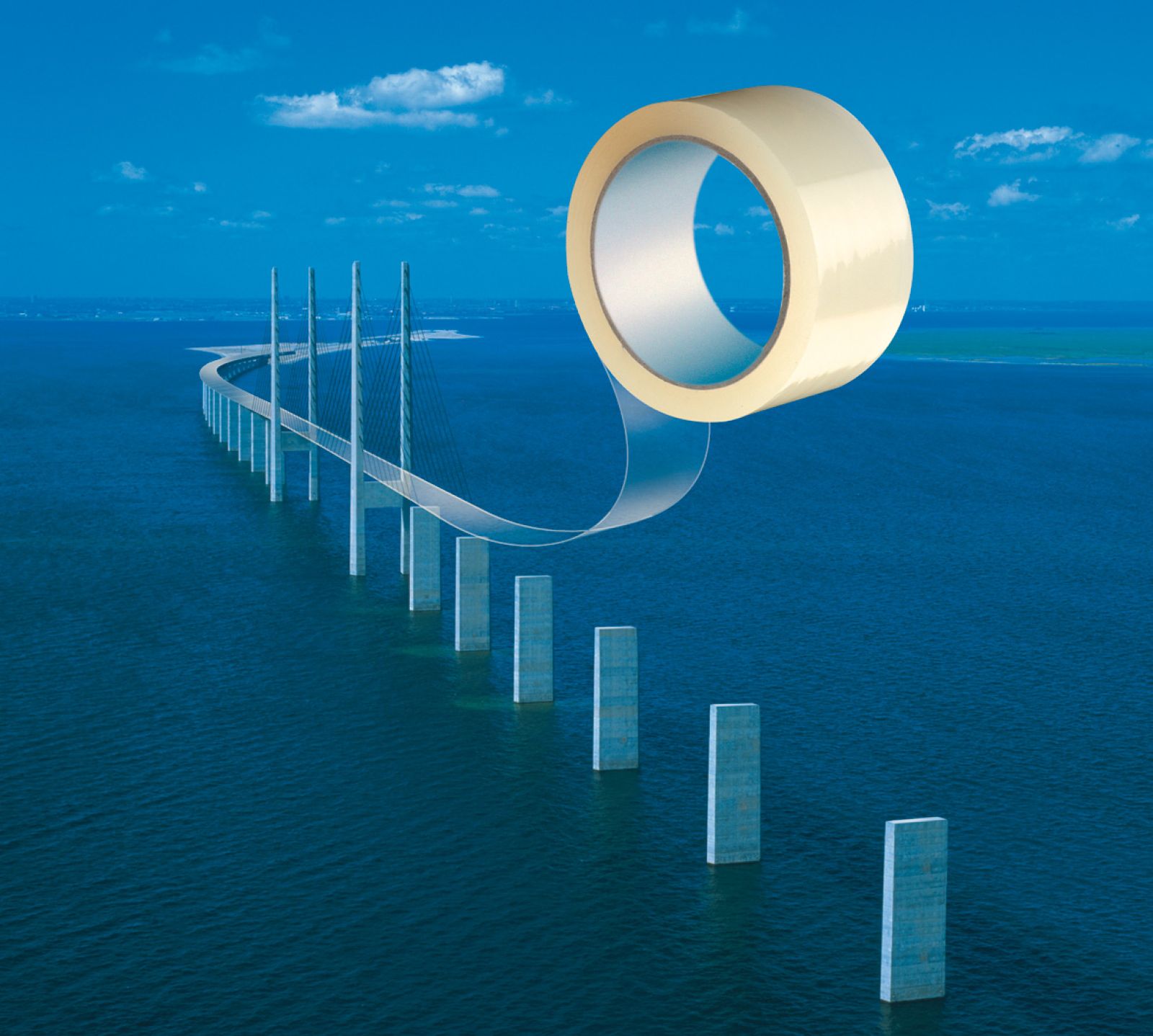

According to one of Afera’s Athens Conference’s most popular lectures, making products smart—putting barcodes on one of their elements, such as tapes or films—can create very high interaction rates, issuing enormous amounts of data which can be processed with machine learning to give new insights. Co-Founder of IoT cloud pioneer EVRYTHNG Andy Hobsbawm urged companies to take advantage of the gains of getting in early on the digitisation of the articles that go into products. “This isn’t about the physical packaging layer anymore but the data layer that goes with it,” he explained. “Tapes and films will become a vehicle for data and software interfaces.” And there is a lot of return on investment on this in terms of efficiency.

According to one of Afera’s Athens Conference’s most popular lectures, making products smart—putting barcodes on one of their elements, such as tapes or films—can create very high interaction rates, issuing enormous amounts of data which can be processed with machine learning to give new insights. Co-Founder of IoT cloud pioneer EVRYTHNG Andy Hobsbawm urged companies to take advantage of the gains of getting in early on the digitisation of the articles that go into products. “This isn’t about the physical packaging layer anymore but the data layer that goes with it,” he explained. “Tapes and films will become a vehicle for data and software interfaces.” And there is a lot of return on investment on this in terms of efficiency.

The future belongs to the companies that can help create products just like the people who are born digital

Just like companies today must get their personnel online, so too should they invest in digitalising their products. Both business and retail are moving to data-enriched channels, and as customer trends shift, businesses need to adapt. This also means that new business models and opportunities can be created—that businesses can become more competitive.

Calling it “a big deal and a fairly seismic shift”, Mr. Hobsbawm has been working with GS1 and the World Wide Web Consortium (W3C) to create the first web standard for bar codes, of which the new version, Digital Link, has just been launched. Digital Link allows the consumer to scan the product in addition to the parties in the upstream supply chain. “This is huge when you think about the 4 trillion consumer products produced each year and the 5 billion scans performed each day, and now you have 2 billion Android and Apple devices which can natively scan barcodes,” said the IoT specialist, who has been listed among the 100 top digital influencers by Wired U.K.

How do you roll out the smart product process as a tape manufacturer?

How do you roll out the smart product process as a tape manufacturer?

- Put the digital triggers on your products: If you are supplying tapes to a product or its packaging, and you want to be part of the production of the smart product, your ability to provide tapes with unique identifiers to products is a manufacturing question.

- Connect the products using a cloud data platform: Once the identifiers are put on the products, they will automatically spin up their profile in the cloud, and the data is captured.

- Write applications: Either you or your ultimate brand will do this for the supply chains and the consumers, and you can start to utilise this data.

- Get analytics: These will tell you exactly what is happening with your products.

“Entering the smart product manufacturing process is quite powerful, because it allows a company to be part of a connected ecosystem,” Mr. Hobsbawm said as he illustrated with slides and video the process and “the world of insights” and opportunities it creates in supply chain efficiencies, stock monitoring, reduced counterfeiting and grey market losses.

Download the complete slide presentation of Andy Hobsbawm (access code Athens2018)

Go to overview of articles on Athens Conference topics

Learn more about Afera membership