Interview with Nitto EMEA President & CEO Sam Strijckmans

As President & CEO of Nitto Europe, the Middle East and Africa since 2016, Sam Strijckmans oversees an organisation of almost 2,000 employees, 6 factories, 10 sales offices and 2 R&D centres spanning the European continent, including Russia and Turkey. I caught up with Mr. Strijckmans recently in London at the Nitto ATP Finals, of which Nitto is the  title sponsor through 2020. On behalf of Afera, I was able to ask him a variety of questions about his career, Nitto and his thoughts on small and medium-sized tape manufacturers and the European market.

title sponsor through 2020. On behalf of Afera, I was able to ask him a variety of questions about his career, Nitto and his thoughts on small and medium-sized tape manufacturers and the European market.

Key takeaways from our discussion

- Small and medium-sized enterprises (SMEs) can be much more flexible because of their smaller-scale business hierarchies, and they very often enjoy close relationships with customers in their locales

- Entrepreneurial spirit can be cultivated in large companies too

- The European adhesive tape industry has a positive future ahead of it, not in commodity but in specialty tapes

- The luxury goods and domestic appliances sectors are particularly interesting for new tape solutions

- Europe is at the cutting edge of both innovation and production of specialty tapes, innovation often occurring in countries such as Italy, France, Germany and Scandinavia and production largely in Central Europe and Turkey

- Nitto aims to create products in the very region where its customers are based to satisfy their local needs

- Nitto is concentrated on innovative electronics for cars in Munich, where its second European design centre was recently set up

- In addition to avoiding “the commodity trap”, SMEs need to integrate European regulatory compliance into their business structures

- Afera offers its members quality access to view the tape market and to contact its most important players

- Because the tape market is so wide, SMEs have to find their unique space in the diversity; this becomes their competitive edge.

Joining Nitto

How long have you been in the tape business?

I have actually been in the films business since 1997, when I started working for Solutia, which is now a subsidiary of Eastman Chemical Company. My focus there was not on adhesive tapes but films—polyvinyl butyral sheets—used in manufacturing laminated glass for auto windshields and architectural glazing. Then, in 2004, I joined Nitto, where I have been now for 14 years.

What made you decide to join the tape business?

At the time I had been living in Switzerland and working for Solutia for 7 years. They asked me to move to their headquarters in St. Louis, U.S., and I refused, so I migrated back to Belgium, where I found a position with Nitto at its (then) European headquarters in Genk.

Moving from a purely American to a Japanese culture in companies was a huge change, but after a few years, I really started to appreciate the Japanese way of doing things as well. As long as you have fun in a company and get to take on a new challenge every few years, you will thrive. I prefer building a career internally—within a company—rather than moving from job to job among different organisations.

Acquiring Nitto Bento

What sorts of challenges are you interested in?

In Nitto, I had the chance to participate in the acquisition of the largest tape manufacturer in Turkey, Nitto Bento, which we acquired in 2012 after proposing it to our headquarters in Osaka. They said, go ahead, but you have to integrate it, and so I moved to Istanbul for 2 years.

That must have been an interesting experience!

It was. I did the post-merger integration of Bento together with one of my Japanese colleagues, and it was a good time for us. In 5 years, Nitto Bento has grown from 240 to nearly 500 employees, so the company has developed nicely.

Bento was originally a family-owned type of business. We had to usher them into a multinational environment with a myriad of rules and regulations relating to compliance. You have to figure out how to strike that balance of compliance—safety, for example, is a top priority for us—and encouraging the continued entrepreneurial culture of a family-owned business. This was our challenge: Not to overload them with too many constraints.

Being entrepreneurial and flexible

How do you view the culture of small businesses then? That they are more entrepreneurial? More flexible?

You can also be entrepreneurial within a large company if the culture allows for it. So long as employees have the motivation to put their own ideas into action, to create something. True, the decision-making process is often quicker and easier in smaller companies, because the owners are more accessible; whereas in multinationals, you can take decisions up to a certain level, and beyond that, after a lot of preparation, you have to go to headquarters to present and defend the business case. In this sense, SMEs can be much more flexible.

Do you think Nitto has that culture which allows you to react quickly to the market—to be flexible?

We have a very clear corporate philosophy consisting of a set of values that every employee has on him at all times. These include “Take on new challenges”, “Have a pioneering spirit”, “Don’t fear failure” and “Have curiosity and passion”. Nitto encourages activities such as creating new business. We also promote a “spirit of open, fair, best”, i.e. having a mindset of modesty and integrity.

Also important is “acting with CSC”—with a sense of crisis, speed and communication. This is what we strive to practice, and it goes along in keeping the entrepreneurial spirit alive within a large company. Our philosophy is published in all the local languages where we operate around the world, so in Europe that includes English, Dutch, Hungarian, Czech and Turkish.

Nitto also organises yearly training sessions on our core principles for all managers worldwide. I give these CP Workshops together with our general manager at each EMEA location.

The future of the European tape market

Where do you think the European tape market is headed?

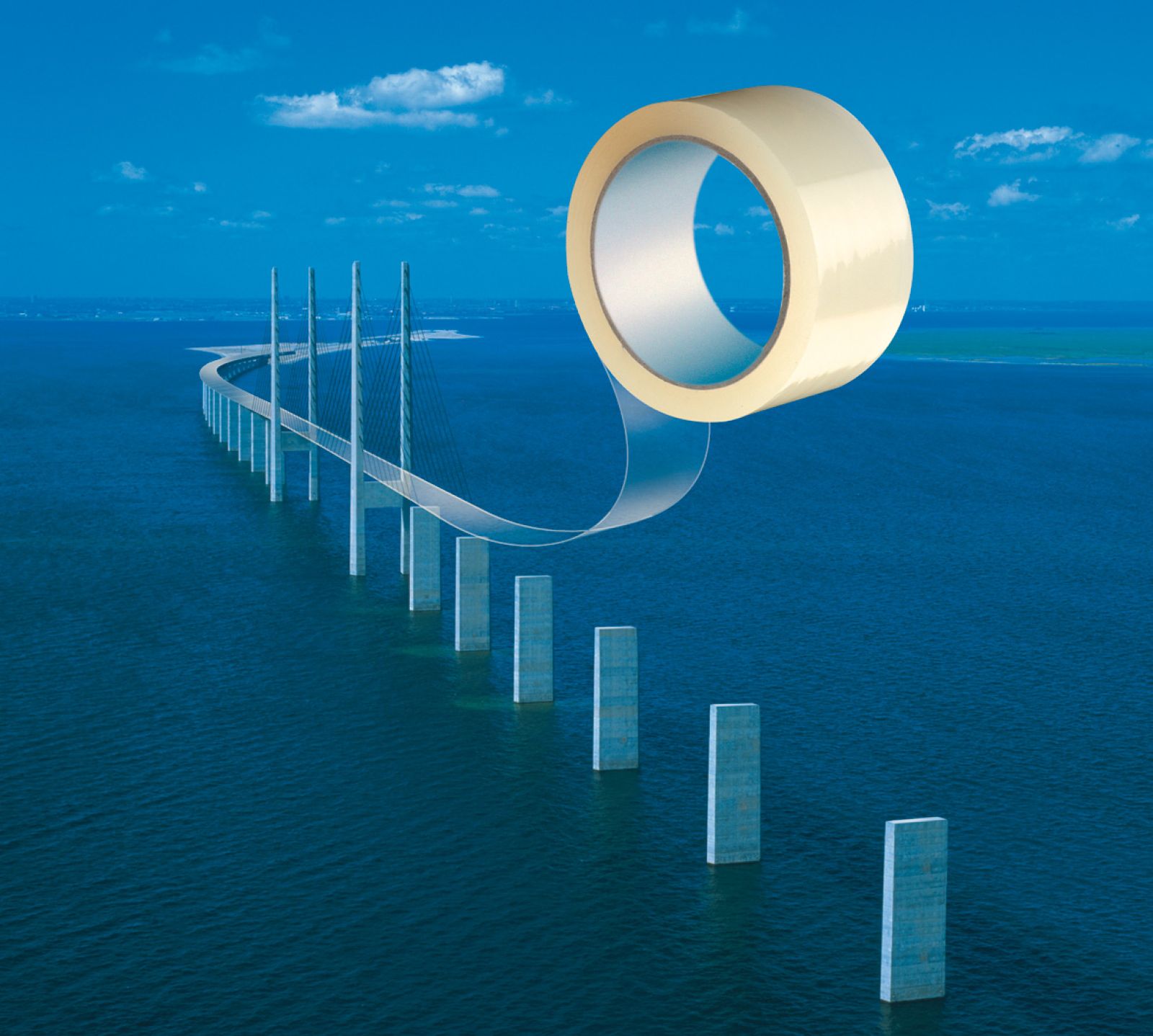

Honestly, I see a relatively positive future for tape in Europe, as long as we try to stay away from purely commodity tapes, such as packaging or box-sealing tapes. We simply cannot compete with the prices of importers from China and other countries where labour and materials costs are lower.

But tape can have so many functionalities: We say tape is “a functional sheet”. Depending on what the customer wants, we can give it a variety of functions. That is where we see a trend of customers needing new functions. European tape makers are trying to replace screws and nails and other complicated bonding and fixing solutions with tapes. So when you work on developing specialties or creating new functions in tape, the effect is positive.

Do you think developing specialty functions of tapes is Europe’s competitive edge then?

Yes, and we see that happening in electronics, furniture—in many different sectors. Think of labels that are not only printed but now have other integrated functions. And, of course, all these tape products incorporate the environmental requirements in which Europe is leading.

The luxury goods and domestic appliances sectors

Can you mention any market sectors in particular that are really interesting for European tape manufacturers?

Of particular interest is the luxury goods market. The top designers of luxury bags, for example, use tape in their manufacturing process. They prefer double-coated tapes to glues, which they think is messy and sticky and tends to negatively affect the premium leathers of their products. It is a dispersed market, because there are many makers of luxury goods, but it is a very interesting one.

Can you reveal a few of your customers in this sector?

Louis Vuitton, Gucci and Prada, to name a few.

An interesting market in Europe is certainly still domestic appliances. This is, of course, a price competitive market, and many makers like Electrolux, Miele and Bosch Siemens Hausgeräte are increasingly using tapes in their final products.

The trend toward innovation and design in Europe

With the trend toward more stringent safety and environmental regulation in Europe, do you think domestic tape manufacturers will be able to stay competitive with Asian makers?

Yes, definitely. Europe is at the cutting edge of innovation toward quieter, more energy-efficient domestic appliances. We are trendsetters in this sense. Any noise or vibration made by a washing machine or tumbler, for example, can be reduced by using tapes.

Is Europe leading in both the design and manufacturing of products utilising specialty tapes?

Yes, in innovation and still in quite a lot of production utilising specialty tapes. Of course, a lot of European production takes place in Central Europe and Turkey, but a lot of specification work is done in design centres in countries such as Italy, France, Germany and Scandinavia. The first step in the production process takes place where the designs are made, and ultimately your sales end up in the countries where the products are manufactured.

Where are your European design centres located?

We have an innovation centre in Genk, Belgium, focussed on automotive, train and aircraft called our TTC (Transportation Technical Centre), where we mainly work on NVH (noise, vibration and harshness) solutions. Here we develop, test and analyse everything having to do with reducing noise and reinforcing materials. At the same location, we also have our BTC (Base Technical Centre), which has to do with sampling, testing and manufacturing new adhesives for industrial tapes.

A couple of years ago, we created a TTCE (Transportation Technical Centre for Electronics)—that is, a facility focussing on innovating electronics for cars—in Munich, Germany. Nitto is active mainly in Asia when it comes to electronics for flat screens, smart phones and tablets. Films in screen technology are increasingly integrated into cars, particularly the self-driving cars of the not-so-distant future. So in Munich, Nitto is right there working on new car electronics with BMW, Daimler and the Volkswagen Group, combining personnel from our tape division with those from the screen technology division to develop new solutions for the car industry.

This is what we call “Area Niche Top”. We want to create products in the very region where our customers are based, to satisfy their local needs. To accomplish this strategy, you need localised marketing and R&D. We cannot rely solely on the developments coming out of Japan anymore. We have to design and to innovate our own solutions.

Nitto’s European presence

So, you have 6 outfits in Europe?

Yes, we have around 1,800 employees in Europe and 6 factories, 3 of them real manufacturing companies. The largest and oldest one is located in Genk, with approximately 650 employees. The next largest is Nitto Bento in Istanbul, with nearly 500 employees to date. We are also in the process of setting up a factory in Brno, Czech Republic, which currently employs about 120 people and is geared toward the automotive market.

In addition to these, Nitto has 3 converting sites in Hungary, the U.K. and Turkey. These are focussed on transforming base materials into final shapes—making pieces and specific forms. Then we have 10 sales offices across Europe, including Russia. Finally, we are looking to enter into Africa as it is also part of “EMEA”.

The threats of Asian competition and REACH

If there were one threat that you perceived in the European market that you would warn other tape manufacturers about, what would it be? Beware of Asian competition? Consolidation?

European tape manufacturers need to get out of the commodities trap. Stay away from general purpose packaging tapes, because I do not see a lot of future for European companies there. Besides this, companies need to stay on their toes about complying with Europe’s regulations. We all know the E.U. is the trendsetter in environmental legislation, and everyone is going to have to learn to make greener, more REACH-compliant solutions.

Facing E.U. environmental regulation and the green trend

Do you think there is a profitable future for companies instituting sustainable practices and producing environmentally friendly products?

Yes, but it is a stepwise process. It is not going to happen overnight. If you have an R&D team, they should be working on developing REACH-compliant products. Otherwise you will have to recruit employees to work on this aspect of business.

Many small companies find this a challenge, because they simply might not have the resources to develop sustainable products or put greener practices into place. Are they in danger of being left behind in the developing market?

You do not have to do this all by yourself. If you are an SME, you can seek support in certain institutions, universities or associations such as Afera, that have the knowledge and expertise in-house or can point you in the right direction for developing a plan to meet your regulatory challenges. Yes, becoming REACH-compliant typically requires an investment which is not recovered the day after it is made. It takes time, but it will happen. So investment in environmental business policy must be made.

Particularly at our operations in EMEA, we are continually investing in improving safety and putting environmental practices into place. The first step is in producing tapes in a more environmentally friendly manner. The second step is figuring out how to use environmentally friendly raw materials. Every company should focus on these two aspects.

Last year we installed a co-generation unit in order to produce our own electricity in the factory in Genk. It is now up and running, and we are producing 30% of our own energy.

We have also installed a solar park. So far, it is only generating 3% of our total electricity used in the factory, but at present we can at least say that all our administrative offices are now CO2-neutral. The solar cell investment has a payback between 10 and 12 years, so it is not an investment you should make for purely economical reasons. We simply think we have to manufacture in a sustainable way, so we are on our way to doing it.

Afera

We see Nitto’s commitment to Afera in the quality and dedication of people participating in our activities. How exactly does Nitto view the importance of the Association?

Nitto has been a contributing member of Afera for many years. I have seen that when colleagues participate in the programmes and projects, they end up in good contact with partners in the market. Of course, a business cannot work on its own in the market. For example, we engage with SMEs in countries where we want to get closer to the market. Obtaining this local information and support is something we cannot do entirely within our own organisation. In some cases, meeting with localised SMEs is crucial to our business.

We also engage with our competitors at Afera, and I think the Association does a good, professional job of informing its members about complying with E.C. Competition Law in all of its operations. This goes for reminding committee and working group members at the beginning of all their meetings what subjects may not be discussed. In short, our membership in Afera offers us quality access to view the tape market and to contact its most important players.

Do you see Afera as a facilitator of meeting with the entire tape value chain or mainly your direct competitors?

We do see our competitors within Afera, but for us it is more about keeping up on the trends and developments in technology, the market, public affairs.... At the end of the day, every member company participating in Afera goes home with a lot of contacts and information, but it is up to us in each business to figure out how we are going to use these tools.

Advice to the SME tape manufacturer

If you could give a piece of advice to an SME tape manufacturer, or to someone setting up a tape business this year, what would it be?

Because the tape market is so wide, they have to find their unique space in the diversity. They need to think strategically—to ask themselves, where do I want to play in this market? Where do I want to make a difference in terms of product quality or specialty? This is the first step. SMEs have the great benefit of being very close to the customer locally almost on a daily basis. This is a great benefit to them, and if they can show value to their customer by intensive interaction, then I see a good future for them.

Questions and comments?

Sam Strijckmans

Senior Corporate Vice President

President & CEO

Nitto EMEA NV

sam.strijckmans@nitto.com

www.nitto.com

Diestsepoort 1

3000 Leuven

Belgium

+32 477 57 16 99