Sustainability

Afera has set up a Sustainability Working Group (Sus-WG) led by Afera Regulatory Affairs Manager Pablo Englebienne and assisted by Charlotte van der Voordt. Including several members of the entire adhesive tape value chain, the WG has one purpose in mind: promoting adhesive tapes as sustainable solutions.

Afera’s sustainability mission

To facilitate the promotion of adhesive tapes as sustainable solutions, i.e. to raise awareness of tapes improving recyclability, reducing weight, economising in materials use, etc.

The WG guides Afera Members’ understanding of sustainability by providing tools such as framework presentations, standardised life cycle analyses, relevant political and legal information, and support in government and NGO relations.

Afera strives to represent the European adhesive tape industry on sustainability and other environmental, social, regulatory and technical issues, actively approaching adverse policy development with counter-evidence and focused positioning.

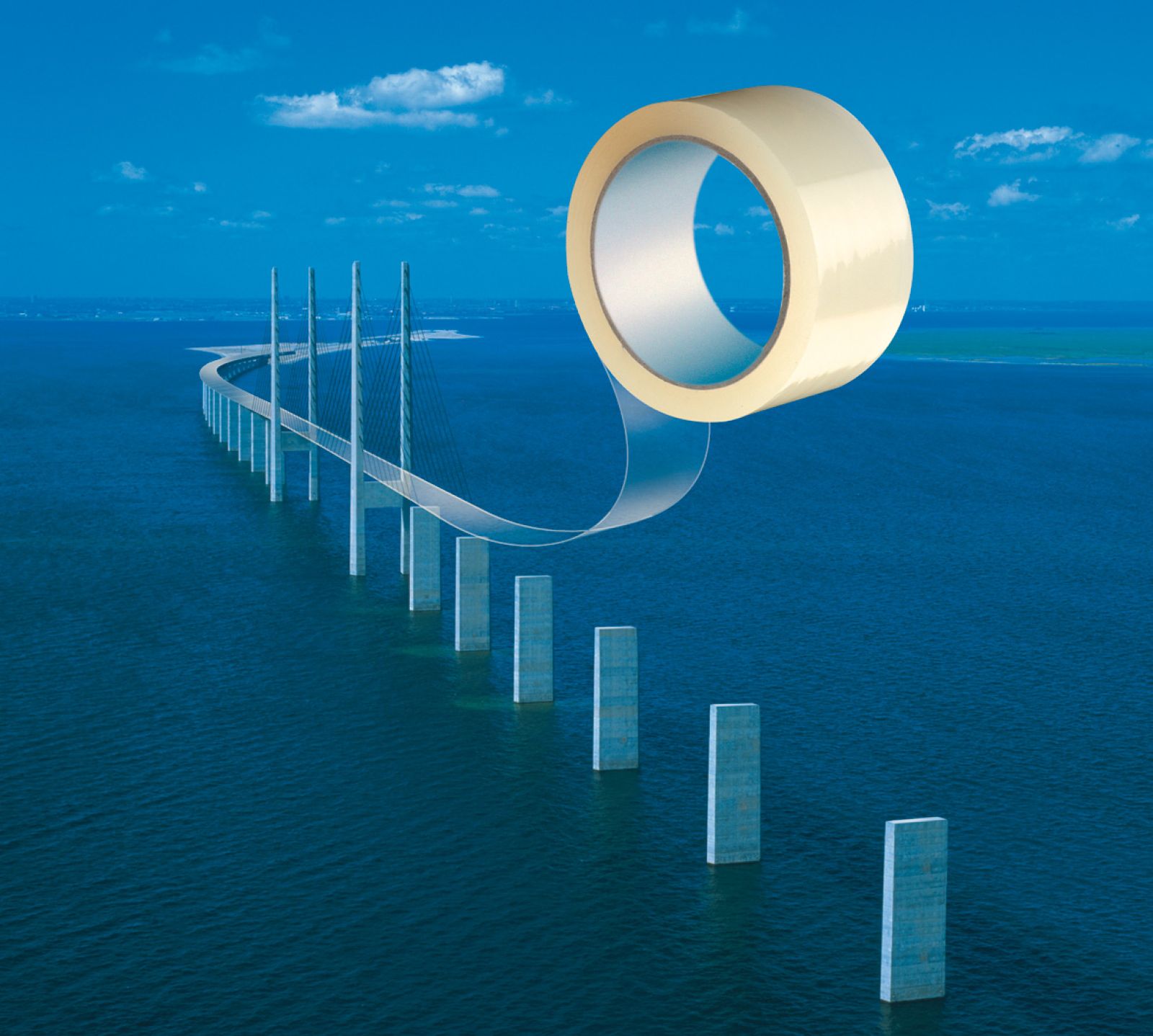

![]() In Afera’s mission statement, 4 of the U.N. Sustainable Development Goals are recognisable: planet, people, prosperity and partnerships. The Industry is working on sustainable solutions that will improve recyclability of the products into which tapes are incorporated. This is not only good for the planet, but it is what people want because it improves and protects their environment. Prosperity comes out of using an efficient, rational approach to sustainable development, with companies designing better products and forging beneficial partnerships to help themselves, the Industry and society reach our goals.

In Afera’s mission statement, 4 of the U.N. Sustainable Development Goals are recognisable: planet, people, prosperity and partnerships. The Industry is working on sustainable solutions that will improve recyclability of the products into which tapes are incorporated. This is not only good for the planet, but it is what people want because it improves and protects their environment. Prosperity comes out of using an efficient, rational approach to sustainable development, with companies designing better products and forging beneficial partnerships to help themselves, the Industry and society reach our goals.

Afera Flagship Sustainability Project

In 2021, we launched our Flagship Sustainability Project “Translating the European Green Deal to Afera Members.” This focuses on making standardised data and calculations available to Afera Members, establishing legislated best available techniques for waste management and reduction along the adhesive tape supply chain, and providing all relevant information about the EGD to Member Companies through an established link between Afera and the European Commission. In June 2021, Afera released a statement entitled “Adhesive tapes are the hidden drivers of industry towards climate neutrality by 2050” detailing the European adhesive tape industry’s support of the EGD.

After much Member and external input, analysis and preparation, the Sus-WG held its kick-off AFSP meetings in November.

3 Workstreams (WSs) have been defined with the key project goals to

- Develop harmonised calculation methods for environmental impact of all types of adhesive tapes (WS1)

- Improve the management of waste that is generated during tape manufacture and use (WS2)

- Anticipate upcoming sustainability regulations and engage with relevant stakeholders to advocate for the tape value chain (WS3).

2 rounds of monthly meetings have already taken place to identify key action points per WS. The next meetings will take place on 13, 14 and 20 January 2022.

Sustainability edition of Afera News

Update on AFSP

Information and registration for AFSP Workstreams

E.U. sustainability initiatives affecting the adhesive tape value chain:

European Green Deal

Circular Economy Action Plan

E.U. Plastics Strategy

Ecodesign

Sustainable Products Initiative

Chemicals Strategy for Sustainability

Related resources:

Afera statement “Adhesive tapes are the hidden drivers of industry towards climate neutrality by 2050” detailing the European adhesive tape industry’s support of the EGD

Afera launches Flagship Sustainability Project on European Green Deal, holds online Q&A session for Members during latest Webinar

Afera online Annual Conference 2020 focussed on sustainability and circularity

Why sustainability is important to the adhesive tape industry

European tape businesses cue in on sustainability in waste processing infrastructure and ‘enabling’ function of tape technologies