Tapes in autonomous vehicle design

Overview:

- Tape plays a role in the evolving consumer experience to digitalisation and connectivity.

- Global megatrends affecting Bosch’s strategy include CO₂ reduction and energy efficiency, demographic shift in average age, urbanisation, world connectivity, changing mobility and globalisation.

- Bosch views the future of mobility as automated, connected and electric.

- As cars are decreasingly involved in accidents, their design will become increasingly lighter in order to travel more efficiently

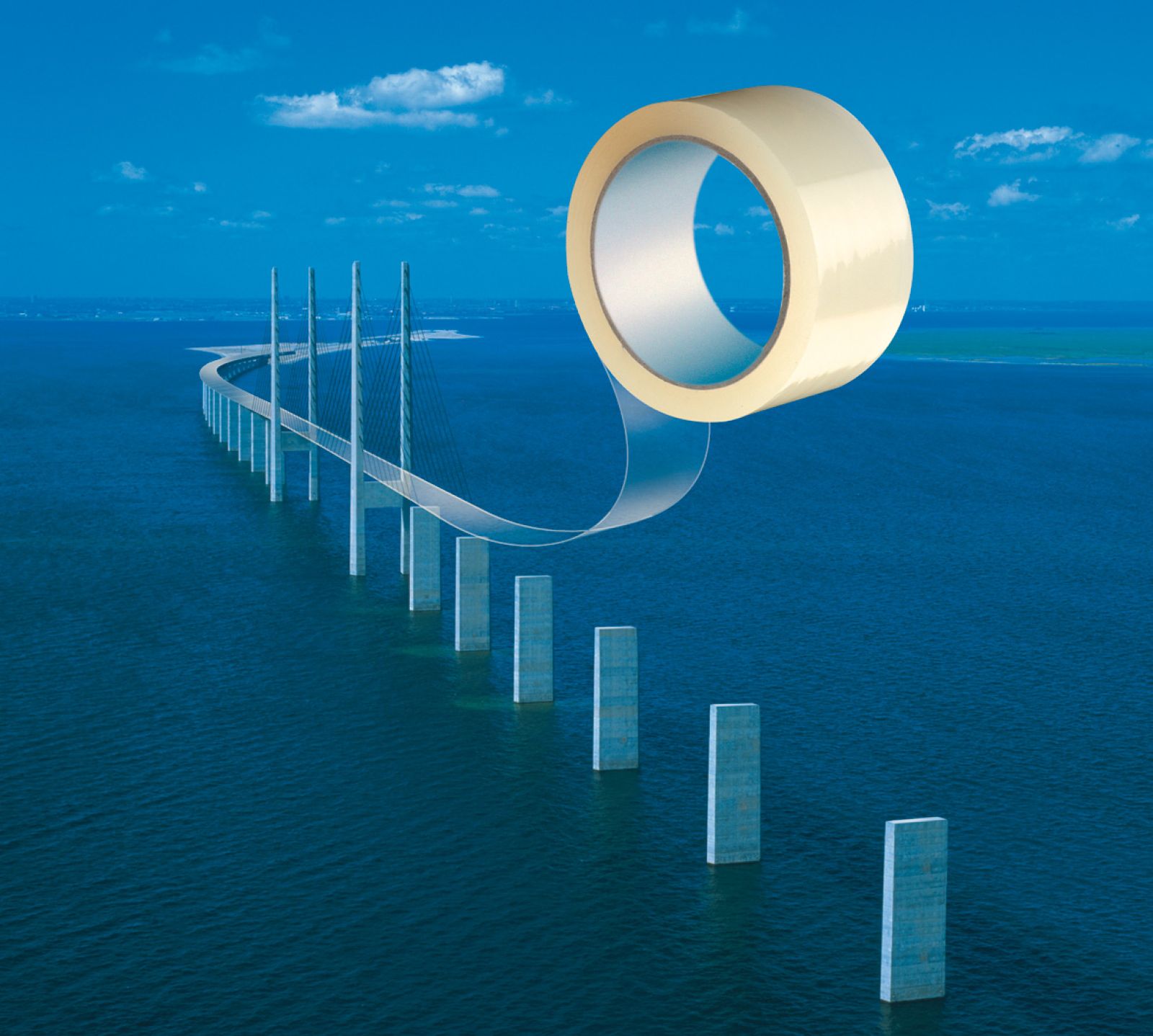

- The autonomous vehicles industry can utilise adhesive tapes as innovative solutions in lightweighting product design.

View the complete slide presentation (members only)

Afera's Marseille conference presentation series

At Afera’s Marseille Conference, Gökhan Tunçdöken of Bosch Mobility Solutions indicated the role adhesive tape could play in the design process of autonomous vehicles. Mr. Gökhan, who is Vice President of Sales Original Equipment, explained both his company’s general strategy according to global megatrends and the development stages of autonomous vehicles in the near future. He indicated that lightweighting product design through the use of adhesive tape is an opportunity for the industry.

The bottom line: From being a mere mode of transport, the car has evolved to become part of a person’s digital lifestyle. Tape plays a role in the evolving consumer experience to digitalisation and connectivity. As cars are decreasingly involved in accidents, their design will become increasingly lighter in order to travel more efficiently. The autonomous vehicles industry can utilise adhesive tapes as innovative solutions in lightweighting product design.

Looking the future in the eye: Bosch

Most people know Bosch as a big white goods producer, but few know that the company makes at least 50% of the total turnover of automotive technologies. Bosch was the first company to produce the automotive ignition magneto.

In addition to automotive technologies and consumer goods, Bosch is active in industrial (Rexroth) and energy and building technologies. With a turnover of approximately €50 billion in 2014, the company has factories in 150 countries and employs around 300,000. Bosch is first in Europe in patent applications, submitting 4,700 every year.

As an innovative technology leader, Bosch expends about 8% of its turnover—around €4 to 5 billion—on R&D, developing the ABS (an anti-lock braking system), the ESP (electronic stability programme) and body electronics, oxygen sensors, injectors and fuel pumps.

Megatrends

Megatrends

Mr. Gökhan listed the major global trends affecting Bosch Mobility Solutions’ R&D strategy:

- CO₂ reduction and energy efficiency: Every industry must be involved in minimising its environmental footprint.

- Demographic shift: The average age worldwide is increasing, and with this, senior products and developments will be in greater demand.

- Urbanisation: Populations are increasingly concentrating around cities, and the number of megacities is growing.

- World connectivity: People have shifted from connecting via computers to connecting via smartphones and tablets, and connectivity in general is increasing. In 1995, ~4 million devices were connected; now it’s 6.6 billion, and in a few years it will reach 50 billion. A great business challenge is keeping abreast of this megatrend and managing the big data that comes with it.

- Changing mobility: With the development of public transportation, social media, its activities, and car sharing, the younger generation is no longer necessarily focussing on obtaining their driver’s licenses and cars, which create the well-known challenges of expense and parking.

- Globalisation: The rise of emerging markets increases the demand for a digital lifestyle, i.e. networked technologies, which include connected products and services such as smart mobile systems, power tools, vehicles, buildings, cities and healthcare systems.

Future mobility: Automated, connected and electric

Bosch’s strategies and R&D activities together focus on the increasingly digital lifestyle, the exponentially increasing rates of connectivity between devices, and contributing to CO₂ reduction by producing electric vehicles.

Autonomous cars can, for example, simplify transportation in urban areas and keep elderly people mobile much longer.

The steps to automated driving

The enabling technologies of autonomous vehicles slated for development by Bosch Mobility Systems:

- Present – Adoptive cruise control (ACC) and lane-keeping support

- 2017 – Integrated cruise assist

- 1028 – Highway assist

- 2020 – Highway pilot

- 2025 – Auto pilot.

Using tape in autonomous vehicle design

In order to make a vehicle autonomous, it is equipped with short and long radar sensors with stereo video cameras with numerous sensors surrounding the car and a lot of data from the cloud. The primary technology behind this is to evaluate all incoming information within seconds and to decide whether to brake, turn, etc.

Bosch is working extensively on this technology and experience in order to release a fully autonomous car by 2025. When this happens, accidents, which are about 99% due to human error, will be reduced, changing the way cars are designed. This is where adhesive tape can play a part in the design process.

Over the last thirty years, vehicle weights have increased by 500-600 kg due to safety regulations. Presently electric cars utilise heavy batteries which, with today’s technology, only enable vehicles to travel 150-180 km at a time. Reducing vehicle weight would make a marked positive difference in driving distance. If the evolution to autonomous driving proves to be safer and regulations are modified accordingly, lightweighting in the design process will remain an important factor. This is a welcome challenge to the tape industry, as tapes are proven enablers of lightweighting in innovative product design.

About Gökhan Tunçdöken

Gökhan Tunçdöken holds a bachelor’s degree in Mechanical Engineering and a master’s in Economy Engineering from the same educational institution in Germany. In 1992, he started working at Bosch San. Ve Tic. A.Ş. as Application Engineer responsible for diesel injection systems. Mr. Gökhan was then appointed as Division Manager  responsible for application of all Bosch Otomotiv products in 1998 and moved on to ESP Customer Project Manager in Germany in 2002. Upon completion of his latest project, he returned to Bosch Turkey in 2004 with the appointment of Vice President of Sales Original Equipment, which he serves to this day. Gökhan is a board member of the Association of Automotive Parts and Components Manufacturers (TAYSAD) and the Automotive Technologies Research & Development Centre (OTAM).

responsible for application of all Bosch Otomotiv products in 1998 and moved on to ESP Customer Project Manager in Germany in 2002. Upon completion of his latest project, he returned to Bosch Turkey in 2004 with the appointment of Vice President of Sales Original Equipment, which he serves to this day. Gökhan is a board member of the Association of Automotive Parts and Components Manufacturers (TAYSAD) and the Automotive Technologies Research & Development Centre (OTAM).

Questions and comments?

Gökhan Tunçdöken

Vice President of Sales Original Equipment

Bosch Mobility Solutions

Gokhan.Tuncdoken@tr.bosch.com